The latest developments in the advanced battery and automotive industries & mobility have been gethering in Stuttgart at the end of june. THE-PLACE-TO-BE to understand and explore WHAT’S HAPPENING IN THE BATTERY INDUSTRY SUPPLY CHAIN, from the latest products and solutions, from raw materials to recycling, from the advanced battery to H/EV technology.

16th International Rechargeable Battery Expo, Tokyo, Japan, February 28-March 1st.

The 16th International Rechargeable Battery Expo Japan, held from February 28th to March 1st at Tokyo Big Sight, Japan, marked a significant milestone in the global energy storage and battery industry. As an integral component of the World Smart Energy Week and organized by RX Japan, Battery Japan has solidified its position as a premier event for industry professionals to engage, share insights, and forge meaningful connections. This expo serves as a vital conduit for the latest technological advancements, trends, and discussions shaping the future of energy storage solutions.

Hymson’s booth, E27-44, became a focal point of interest throughout the event, drawing a consistent stream of visitors. The booth showcased Hymson’s innovative approach to leveraging laser technology in the battery manufacturing process, highlighting presentations such as « Laser as a Perfect Tool for LIB » and « Hymson Laser Notching Products Empower New Energy Industry with Digital Intelligence. » These presentations not only showcased Hymson’s cutting-edge solutions but also sparked engaging discussions amongst attendees. Representatives from Japan’s top automotive and battery manufacturing sectors showed a particular interest, keen on understanding how Hymson’s technologies could be integrated into their operations and contribute to the burgeoning electric vehicle (EV) battery market in Japan.

A few shots from HYMSON booth at the 16th International Rechargeable Battery Expo, Tokyo, Japan, February 28-March 1st.

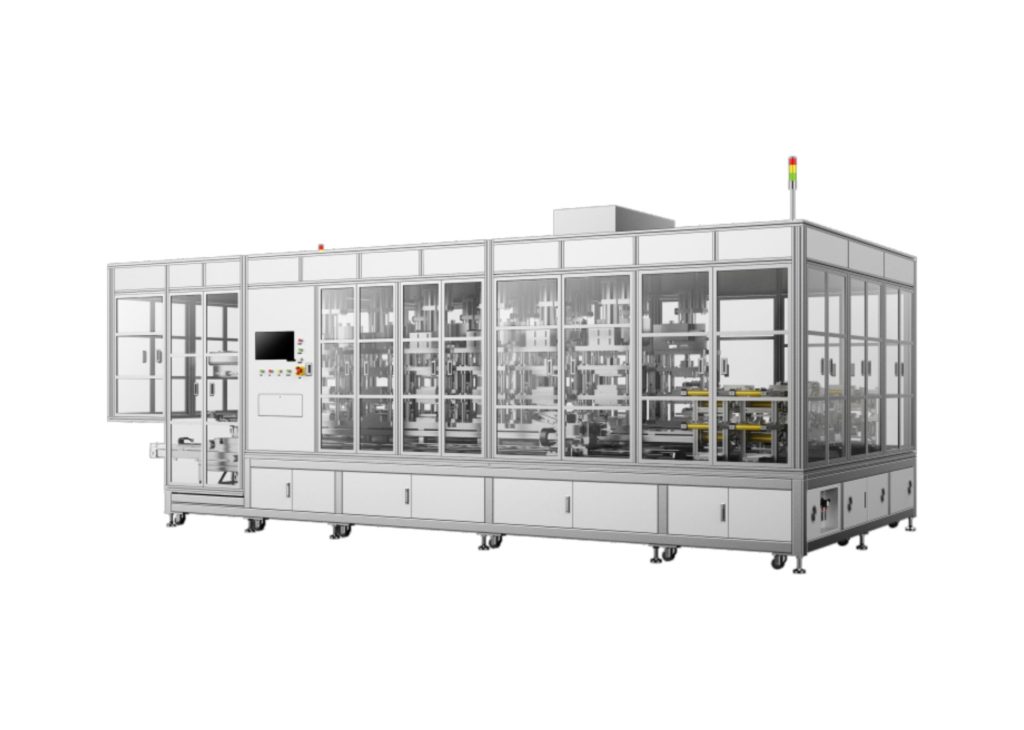

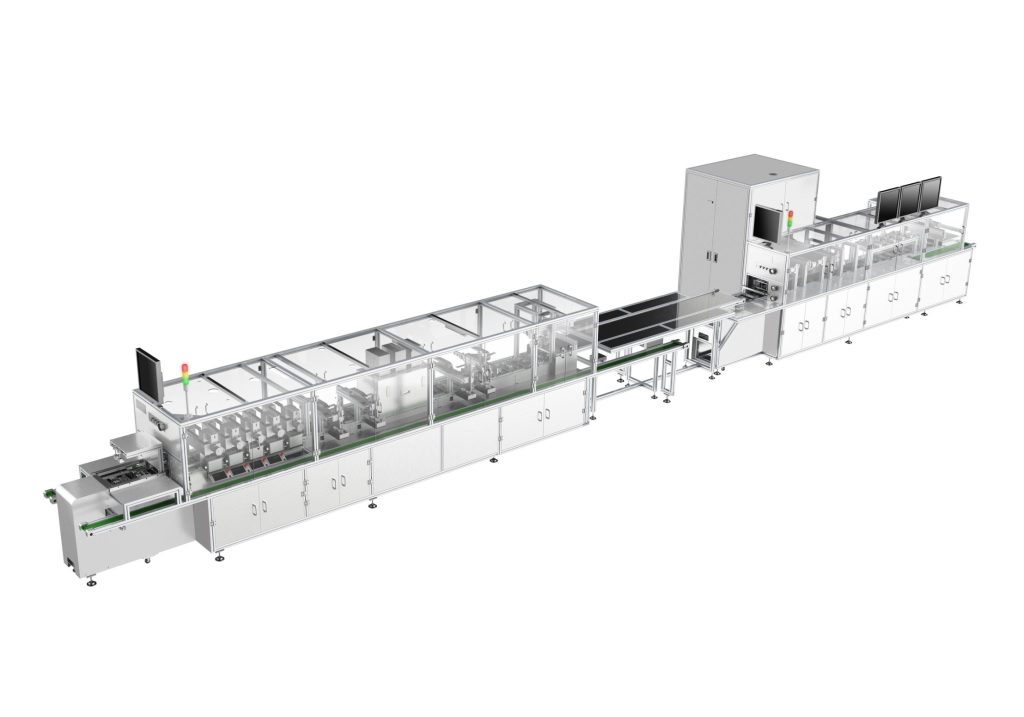

At booth E27-44, the company showcased its latest advancements, drawing the attention of industry professionals and stakeholders. Among the standout products were the Hymson Prismatic Cell Assembly Solutions, and the Laser Notching & Electrode Cutting Integrated Machine, alongside the Laser Notching & Slitting Integrated Machine available in both narrow and wide widths. These offerings underscore Hymson’s commitment to pushing the boundaries of technology and efficiency in the sector.

Hymson, a leader in laser and automation equipment, showcased innovative products like Prismatic Cell Assembly Solutions and Laser Notching Machines at a recent industry exhibition, demonstrating a commitment to advancing technology and efficiency.

The cornerstone of Hymson’s showcase was its advanced laser notching technology, which is pivotal to the company’s reputation for superior product quality and service. This technology is not just about precision; it’s about redefining speed and reliability in laser cutting. The high-speed laser notching machine, a highlight at the exhibition, now boasts a production speed surpassing 120 m/min. This marks a significant milestone, reinforcing Hymson’s position as a provider of choice for customers seeking efficiency and precision.

Hymson has a global presence with over 2000 machines sold worldwide, showcasing its commitment to delivering stable production services globally. Through innovation, the company exceeds customer expectations and shapes the future of laser and automation equipment. Hymson focuses on providing cutting-edge technological solutions to keep customers ahead.

English

English Italiano

Italiano Español

Español