Magda Dellai

Project and Mkt manager, Hymson Italy Srl

Editorial published in the trade journal Meccanica Oggi on Hymson laser cutting plants

june-july 2023

_________________

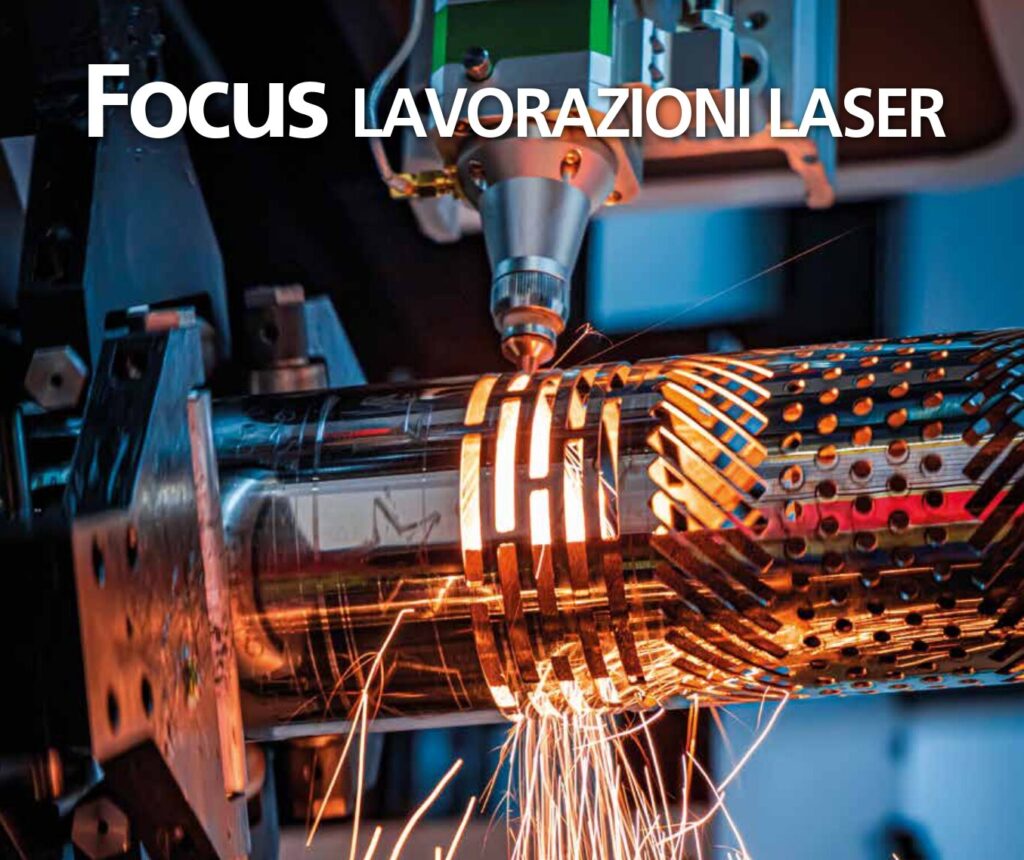

Laser technologies play an increasingly central role in the ongoing evolution of manufacturing processes, which are now increasingly interconnected, agile and fast, and are a key component of Industry 4.0 systems. With the move to Industry 4.0, a process of industrial automation is underway, the aim of which is to integrate a number of new production technologies to improve working conditions, increase productivity and the production quality of plants. In fact, it is a process innovation, which involves its revision and redesign, according to new objectives to be achieved in order to be more competitive in international markets. Laser technology is increasingly proving to be a mature industrial tool to meet these new functional requirements in many industrial sectors. Today, the laser light beam, like a weightless tool with no need for contact, has become indispensable in an increasingly wide range of sectors, from automotive to aerospace, from nautical to electronics, because it allows high precision and speed machining, offers high flexibility in production and is not subject to wear.

Hymson laser cutting machines feature a range of complete solutions offering the highest level of performance and technology for consistently perfect and precise metal laser cutting, thanks to high axis speed and acceleration, together with the rigidity of the machine mechanics. From sheet metal to tube to any three-dimensional metal profile, Hymson laser cutting systems always guarantee maximum productivity and fast changeovers.

READ RELATED ARTICLES

English

English Français

Français Español

Español