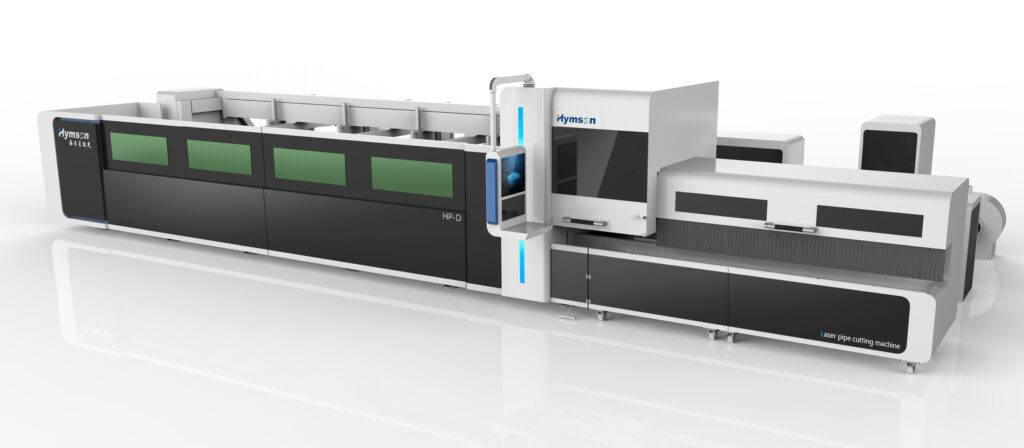

High end system with the latest technology for laser cutting of tubular profiles

The winning choice for the most demanding industry asking for top cutting performance to achieve burr-free and flake-free surfaces, maximum reliability and excellent value for money. The system, at the top of the range in laser tube cutting, is highly automated, with five-axis connection, ultra-fast rotation, high precision mechanical adjustment and positioning. The high degree of automation results in considerable time savings and in a process at controlled phases, not depending on the technical skills of the operator only. The machine can process a wide variety of workpieces, paving the way for new areas of industrial application.

- Automatic loading and unloading system capable of automatically loading a single pipe from a bundle for large batches and mass production.

- 24/7 continuous cycle machining and very high productivity

- The smart dual dust removal system ensures high quality performance when removing dust.

- The CNC control system is The Super Brain from the Hymson brand: developed in partnership with Beckoff, Hymson has created a dedicated format for its machines with unique cutting applications and functions.

- The TwinCAT system has 16 individually adjustable process levels including cutting speed, laser power, air pressure, cutting height and other parameters. Each level is marked by a colour, allowing quick browse and configuration of the cutting parameters graphic.

- User-friendly software: the TwinCAT software, integrated with a number of laser cutting modules with special functions, shortens the machine’s basic learning curve for ease of use and intuitive graphical user interface with a positive impact on production costs.

- The machine meets CE standards.

- Protection class IP 54

Italiano

Italiano Français

Français Español

Español