Top of the range laser cutting machine with optic-fiber technology, automatic loading and unloading system, parallel kinematic technology, tooling with retractable grippers and superior performance in cutting thin materials.

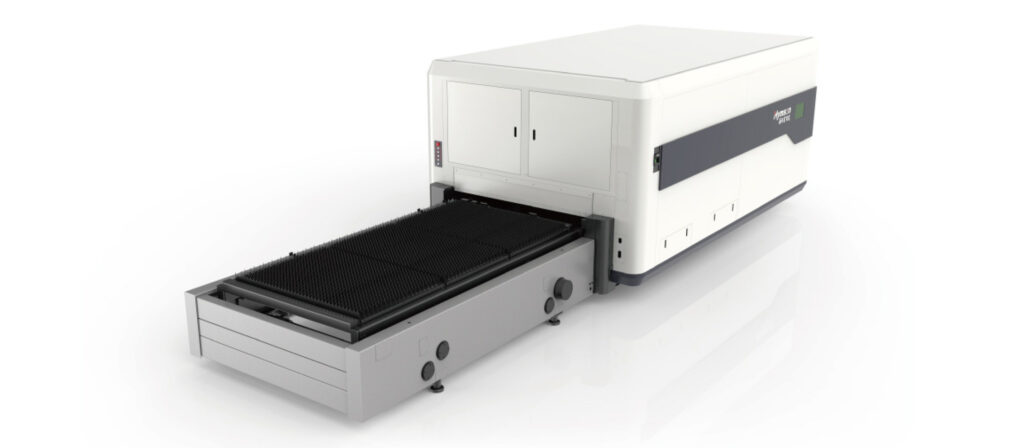

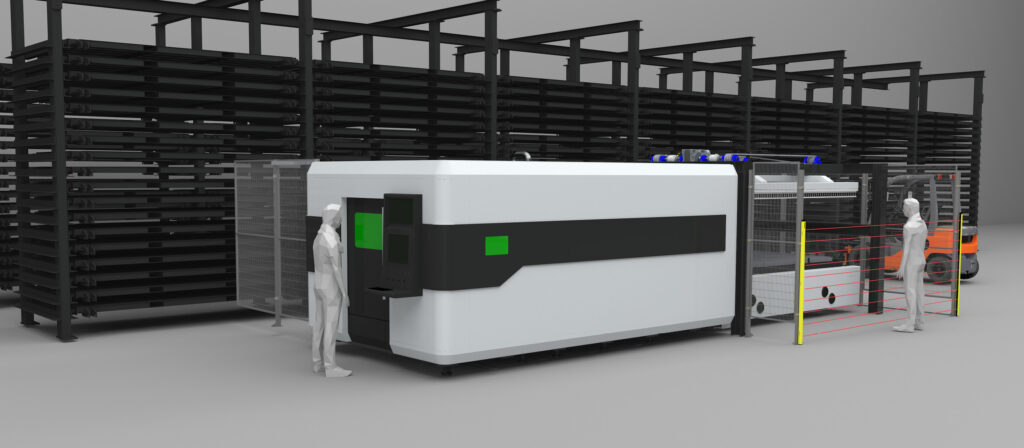

The HF H series is a fully automatic cutting solution with high power laser source up to 12 kW. With exceptional performance in terms of reliability, precision and rigidity, the system is equipped with an innovative “up & down” exchange table and can be integrated with automatic loading/unloading and multi-storage tower systems. The more intensive the use, the greater the return on investment: high speed cutting with low operating costs and low maintenance requirements thanks also to a simple and quick learning intuitive control system.

- Wide range of metal cutting thicknesses <60mm with excellent performance in terms of finishing quality and efficiency.

- The HyLaser 2.0 system provides the possibility of special cuts of Mild Steel, Stainless Steel, Aluminium, Copper, Brass and Galvanized with a thickness of 3-30mm.

- The BECKHOFF ETHERCAT BUS is a control automation technology with outstanding performance characteristics, flexible and self-explanatory in configuration.

- Libellula laser cutting software: a winning formula for + Automation + Integration + Efficiency + Productivity – Learning and Programming Times

- The bridge with newly designed structure is designed for 12Kw+ fiber laser power for maximum strength and stability, with finished deformation < 0.04mm.

- The smart dust and particle extraction system as a complement to the machine helps to extract dust and metal particles while the machine is running to protect the laser equipment and keep the working area clean.

- The machine meets CE standards.

- Electrical protection class IP 54

Italiano

Italiano Français

Français Español

Español