New industrial plant

Model HF 3015 IT

for flat sheet-metal cutting

The project developed in Italy

MADE IN ITALY

It is the latest evolution among the machines developed by Hymson Italy, a product of top level technology, both hardware and software: with high quality performance and unparalleled ease of use, the machine is one of the most versatile and economically viable offered today to metalworking professionals.

Highlights model HF 3015 IT

The machine offers upper performance for customers looking for reliability in technology.

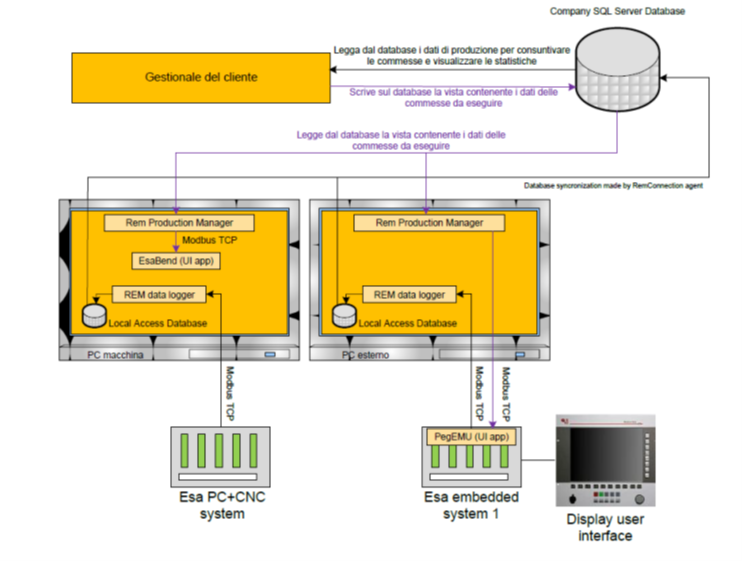

The key components of the system are entirely made in Italy, from the NUMERICAL CONTROL to the MOTORS, SERVOMOTOR and DRIVE, from the SOFTWARE to the INDUSTRY 4.0 INTERFACE. For this project, Hymson collaborates with the best technological and IT partners for cutting-edge CAD and CAM software solutions dedicated to integrated production management in manufacturing companies.

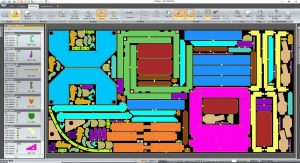

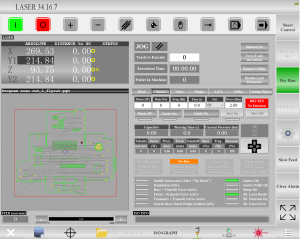

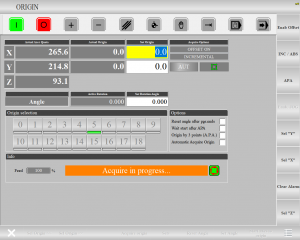

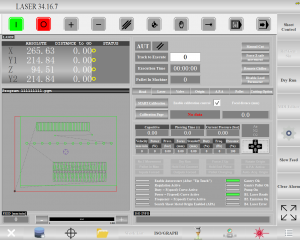

CONTROL DISPLAY

CONTROL DISPLAY

CONTROL DISPLAY

CONTROL DISPLAY

ACCESSORIES ON DEMAND

- 5-axis beveling head for flat sheet metal

- Automatic noozle centering

- Automatic noozle change

- Automatic loading & unloading systems with CNC control

TECHNICAL DATA

|

PARAMETER |

MODEL HF 3015 IT |

|

|

Fiber optic laser power |

1000 ~ 12000 W |

|

|

Working area size |

3000x1500mm |

|

|

Axis X |

Track length |

3000mm |

|

Axis Y |

Track length |

1500mm |

|

Axis X/Y |

Max positioning speed |

110m/min |

|

Positioning accuracy |

0.03mm/m |

|

|

Repetition positiong accuracy |

±0.02mm |

|

|

Max acceleration |

1.8 g |

|

|

Axis Z |

Track length |

280mm |

|

Max positioning speed |

60m/min |

|

|

Max acceleration |

1.8 g |

|

|

Max weight of workpiece |

0.6 t |

|

|

Size /Weight of the machine |

8500x5700x2450 mm / 8.75t |

|

CUTTING THICKNESS MODEL HF 3015 IT

|

LASER POWER MATERIAL |

1500 W |

2000 W |

3000 W |

4000 W |

6000 W |

8000 W |

10000 W |

12000 W |

15000 W |

20000 W |

|

MAX CUTTING THICKNESS |

||||||||||

|

INOX STEEL |

5mm (*6mm) |

6mm (*8mm) |

8mm (*10mm) |

10mm (*12mm) |

14mm (*16mm) |

16mm (*18mm) |

18mm (*20mm) |

20mm (*22mm) |

22mm (*25mm) |

25mm (*30mm) |

|

ALUMINIUM |

4mm (*5mm) |

5mm (*6mm) |

8mm (*10mm) |

10mm (*12mm) |

14mm (*16mm) |

16mm (*18mm) |

18mm (*20mm) |

20mm (*22mm) |

22mm (*25mm) |

25mm (*30mm) |

|

BRASS |

2mm (*3mm) |

4mm (*5mm) |

6mm (*8mm) |

6mm (*8mm) |

8mm (*10mm) |

10mm (*12mm) |

12mm (*14mm) |

14mm (*16mm) |

16mm (*18mm) |

18mm (*20mm) |

|

CARBON STEEL |

12mm (*14mm) |

14mm (*16mm) |

16mm (*20mm) |

20mm (*22mm) |

20mm (*22mm) |

22mm (*25mm) |

25mm (*30mm) |

30mm (*35mm) |

35mm (*40mm) |

40mm (*50mm) |

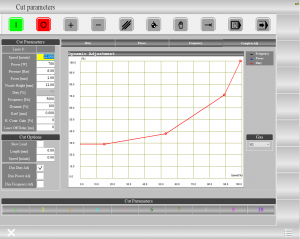

* Higher thicknesses are the result of the operator’s sensitivity, skill in setting the machine’s cutting parameters and material quality.

Italiano

Italiano Español

Español

HYMSON ITALY

HYMSON ITALY HYMSON

HYMSON